Welcome to our website, where we offer a wide range of high-quality silver brazing products that meet the needs of various industries. Our products include silver brazing alloys, cadmium-free silver brazing alloys, silver brazing wire, silver brazing foil and strip, silver brazing rings, silver brazing rods, silver brazing rings and discs, and silver brazing fluxes.

Silver brazing is a joining process that uses a filler metal, which has a lower melting temperature than the base metal being joined. The filler metal is melted and then flows into the joint by capillary action. This results in a strong and permanent bond between the two metals.

Silver brazing alloys are used extensively in the HVAC, refrigeration, and automotive industries, where high-strength, leak-tight joints are required. Our silver brazing alloys are made from high-quality materials and are available in a variety of forms, including wire, foil, and strip. They offer excellent fluidity, wetting, and flow characteristics, making them easy to use and ensuring strong and reliable joints.

For those who are concerned about the health risks associated with cadmium, we offer cadmium-free silver brazing alloys. Our cadmium-free silver brazing alloys offer the same excellent performance as our standard silver brazing alloys, but without the health risks associated with cadmium. They are a safe and effective alternative for those who require high-strength, leak-tight joints without compromising on safety.

Our silver brazing wire, foil, and strip products are available in a range of sizes and thicknesses to suit various applications. They are ideal for use in industries such as aerospace, electronics, and jewelry making, where precision and accuracy are paramount. They offer excellent resistance to corrosion, oxidation, and tarnishing, ensuring long-lasting and reliable joints.

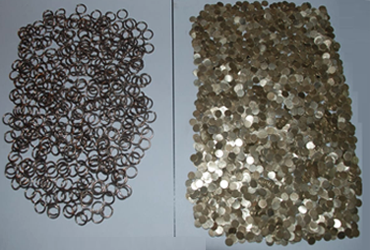

In addition to our standard silver brazing products, we also offer a range of silver brazing rings, rods, and discs. These products are ideal for use in plumbing, HVAC, and automotive applications, where high-strength, leak-tight joints are essential. Our silver brazing rings, rods, and discs are available in a range of sizes and thicknesses to suit various applications, and they offer excellent fluidity, wetting, and flow characteristics, making them easy to use and ensuring strong and reliable joints.

To ensure the best possible results when using our silver brazing products, we also offer a range of silver brazing fluxes. Our silver brazing fluxes are specially formulated to ensure maximum wetting and flow of the filler metal, ensuring strong and reliable joints. They are available in a variety of formulations to suit different applications, and they offer excellent resistance to corrosion, oxidation, and tarnishing.

At our company, we are committed to providing our customers with high-quality silver brazing products that meet their specific needs. Whether you require standard silver brazing alloys or cadmium-free silver brazing alloys, silver brazing wire, foil, or strip, or silver brazing rings, rods, or discs, we have the products and expertise to meet your requirements. Contact us today to learn more about our silver brazing products and how we can help you achieve strong and reliable joints in your applications.

Cadmium free silver brazing alloys

silver brazing wire

silver brazing foil and strip

silver brazing Rings

silver brazing Rods

silver brazing Rings and discs

silver brazing fluxes

A) SILVER BRAZING ALLOYS - Without Cadmium

| KRANTI CODE | Composition % By Weight | Melting Range | |||||

- |

Ag | Cu | Zn | Ni | Sn |

Solids | Liquids |

KM72 |

72 | 28 | - | - | - |

780 | 780 |

KM61 |

61 | 29 | 10 | - | - |

690 | 735 |

KM56ZC |

56 | 22 | 17 | - | 5 |

619 | 652 |

KM56N |

56 | 42 | - | 2 | - |

770 | 895 |

KM50NWC |

50 | 20 | 28 | 2 | - |

660 | 705 |

KM45 |

45 | 57 | 25 | - | 3 |

640 | 680 |

KM40SN |

40 | 30 | 28 | - | 3 |

648 | 709 |

KM38N |

38 | 32 | 28 | - | 2 | 648 | 720 |

KM30 Ni |

30 | 37 | 32 | 1 | - | 675 | 780 |

KM34SN |

34 | 36 | 27.5 | - | 2.5 | 630 | 730 |

B) SILVER BRAZING ALLOYS - Contain Cadmium

| KRANTI CODE | Composition % By Weight | Melting Range | ||||||

- |

Ag | Cu | Zn | Cd | Ni | Sn |

Solids | Liquids |

KM43 |

43 | 16 | 20 | 21 | - | - |

615 | 620 |

KM35 |

35 | 26 | 21 | 18 | - | - |

607 | 702 |

KM40ZC |

40 | 19 | 21 | 20 | - | - | 595 | 630 |

| KM38N | 38 | 32 | 28 | - | - | 2 | 648 | 720 |

| KM30 | 30 | 27 | 23 | 20 | - | - | 607 | 710 |

| KM30 Ni | 30 | 37 | 32 | - | 1 | - | 675 | 780 |

| KM30 NC | 31 | 32.5 | 15.5 | 19.5 | 1.5 | - | 675 | 695 |

| KM25 WN | 25 | 30 | 27.5 | 17.5 | - | - | 605 | 720 |

| KM21 | 21 | 35 | 27 | 17 | - | - | 620 | 730 |

| KM20 | 20 | 38 | 26 | 16 | - | - | 610 | 740 |

As above products are general purpose Silver Brazing Alloy.

C) Brazing Products for Joining of Carbide To Steel

| KRANTI CODE | Composition % By Weight | Melting Range | |||||||||

- |

Ag | Cu | Zn | Cd | Ni | Mn | Co | Sn | Si |

Solids | Liquids |

KM50 |

50 | 15.5 | 15.5 | 16 | 3 | - | - | - | - |

632 | 688 |

KM50NWC |

50 | 20 | 28 | - | 2 | - | - | - | - |

659 | 707 |

KM49 |

49 | 16 | 23 | - | 4.5 | 7.5 | - | - | - |

625 | 705 |

KM49Cu |

49 | 27.5 | 20.5 | - | 0.5 | 2.5 | - | - | - |

670 | 690 |

KM40 Ni |

40 | 30 | 28 | - | 2 | - | - | - | - |

670 | 75 |

KM43 |

43 | 16 | 20 | 21 | - | - | - | - | - |

615 | 779 |

KM31Ni |

31 | 32.5 | 15.5 | 19.5 | 1.5 | - | - | - | - |

675 | 695 |

KMCM27 |

27 | 38 | 20 | - | 5.5 | 9.5 | - | - | - |

680 | 840 |

KM25N |

25 | 58 | 6.5 | 9 | 1.5 | - | - | - | - |

720 | 840 |

KM20N |

20 | 35 | 26 | 17 | 2 | - | - | - | - |

652 | 850 |

KMCMF |

- | 57.5 | 38.5 | - | - | - | 2 | 2 | - |

870 | 930 |

KMCuN |

- | 96.7 | - | - | 2.5 | 0.2 | - | 0.6 | - |

1090 | 1100 |

KMNB10 |

- | 49 | 40.7 | - | 10 | - | - | - | 0.3 |

920 | 980 |